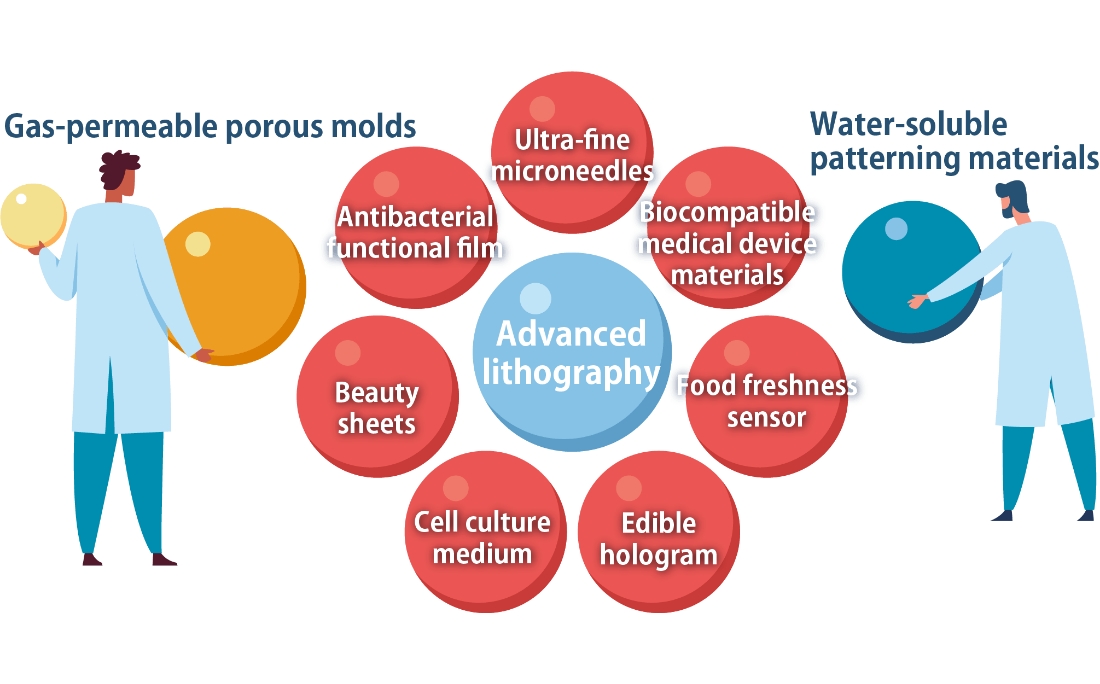

Target・Application

We are researching functional materials and microfabrication technologies that can contribute to people’s health in the life science and healthcare fields, which are expected to grow significantly in the future.

In order to contribute to the development of new products, we are researching the following functional materials and microfabrication techniques that can be subjected to nano/micro surface processing.

Antibacterial functional films

Antibacterial, antifouling, water and oil repellent film, plastic

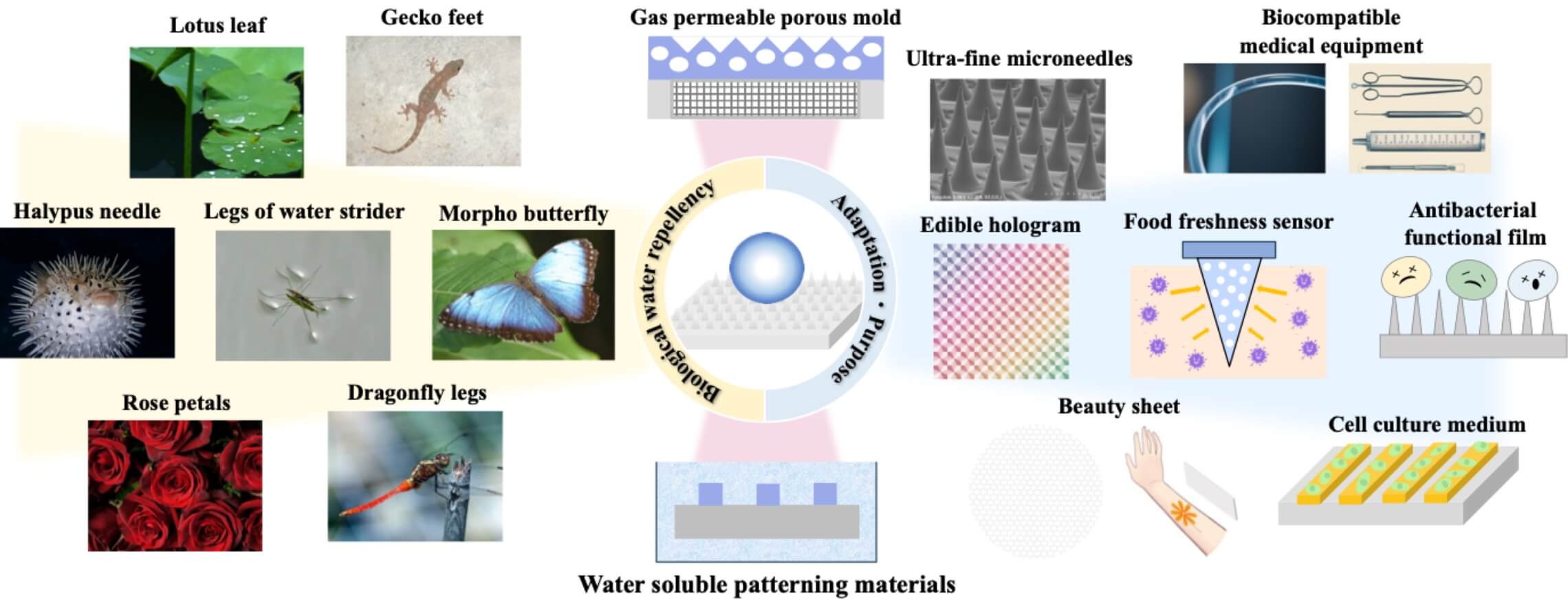

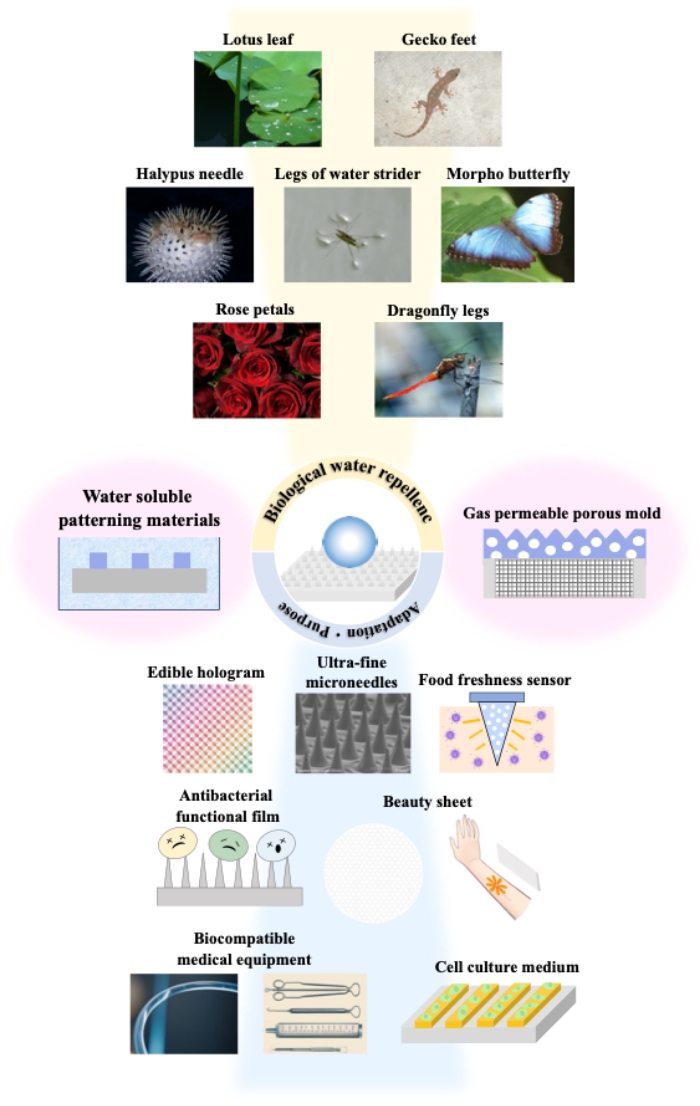

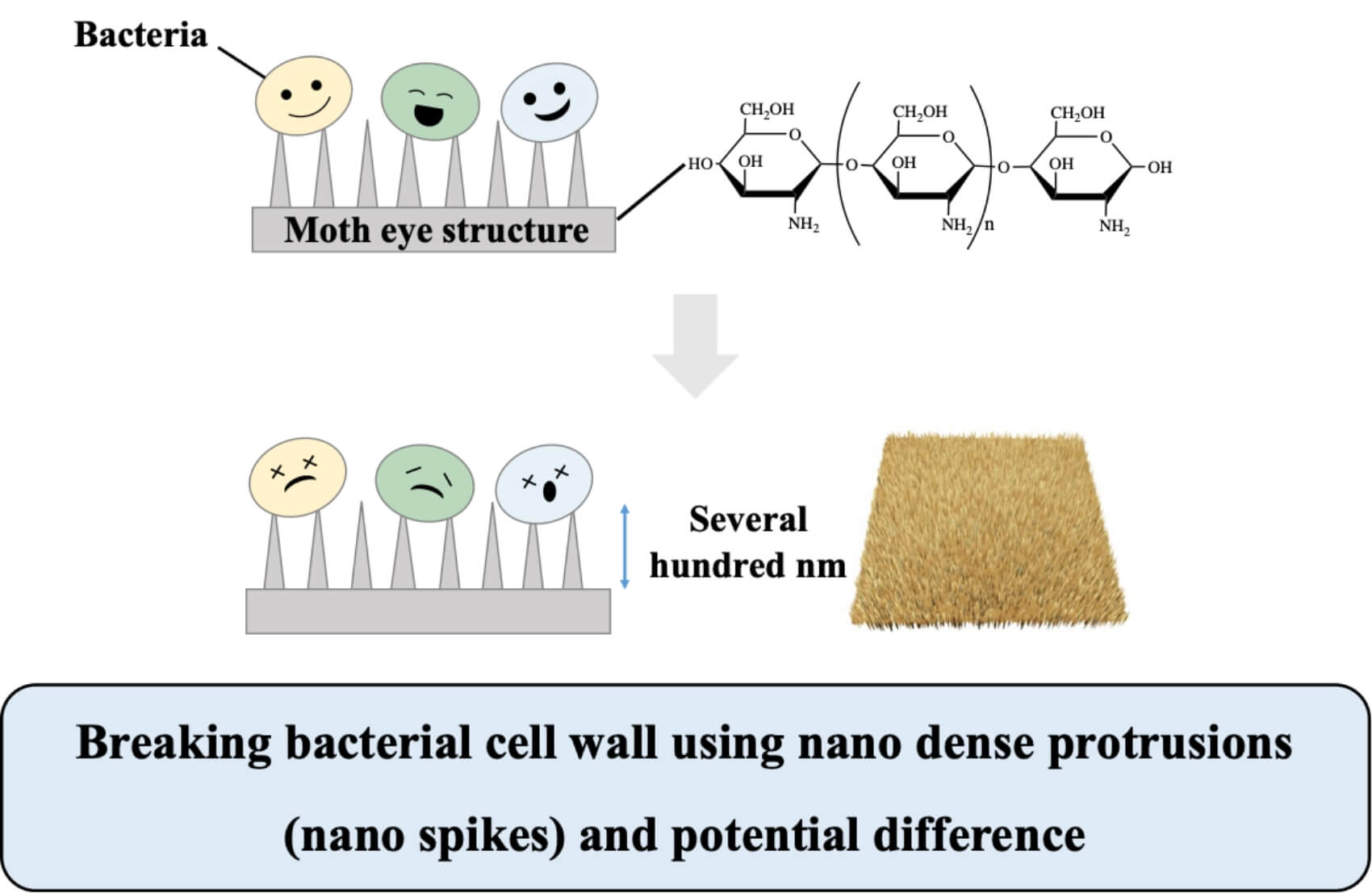

Biomass-derived functional materials with nano protrusions, such as crab-derived chitosan, which is attracting attention as a food for specified health uses, are highly safe and effective in killing bacteria such as Escherichia coli. We are focusing on these materials as new environmentally friendly bioplastic materials, and are researching antibacterial films and antifouling plastics with nano protrusions shape using our proprietary microfabrication and bio-mimetic technologies. We expect to develop applications not only in medical materials and eco-friendly devices, but also in toiletries and electronic products.

Antibacterial products such as sheets, films, patches, and plastics, form a huge market in Japan, worth over 1 trillion yen annually. Common methods of imparting antibacterial activity to products include kneading metallic particulates such as silver peroxide or zinc peroxide, quaternary ammonium salt compounds, and biomass materials such as catechins or chitosan, into the product. Alternatively, the surface of the product can be coated with titanium or bioactive natural ingredients. However, these methods have issues of insufficient antibacterial activity and sustainability.

New technologies focus on antibacterial activity based on the surface microstructure of cicada wings and lotus leaves through biomimetics. Using lithography and biomimetic technologies that support information communication networks and semiconductor manufacturing, antireflective moth-eye films and artificially fabricated black silicon in solar cell have been found to exhibit antibacterial activity due to their nano protrusions. Previous studies have shown inactivation of surface-associated coronaviruses (SARS-CoV-2). In anticipation of the era of with corona and after corona, and in response to growing public awareness of hygiene, Takei Lab. is being researched to further improve antibacterial and antiviral properties by using gas-permeable porous molds and water-soluble patterning materials.

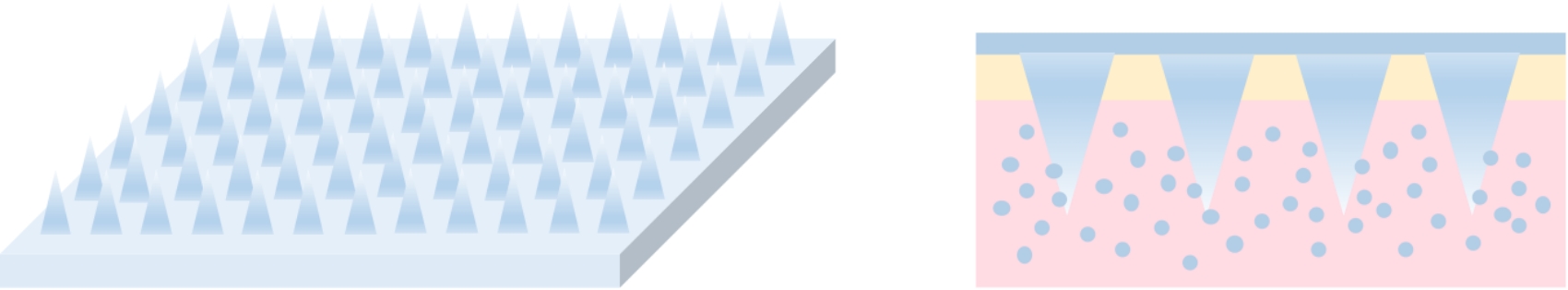

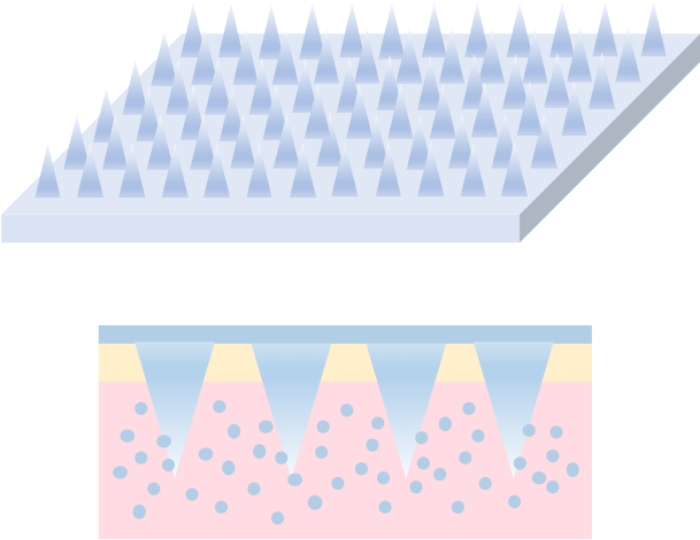

Ultra-fine microneedles

Highly permeable self-dissolving ultra-fine microneedles for medical and cosmetic applications

Microneedles are a technology that will lead to painless “vaccine patches” and “highly sensitive IoT sensing devices.” Microneedles create tiny holes on the surface of skin, through which active ingredients can be administered or absorbed. Compared with injections, we are able to self-administer the drug in a painless, simple, and safe dosage form that does not bleed. In addition, microneedles have great potential because they are convenient to store and transport, there is no needle waste, and they can significantly reduce medical costs and improve patient quality of life.

Type1:Active ingredients fabricated into microneedles

The microneedles (matrix and excipient) are made of collagen and hyaluronic acid, which are natural components of the skin. when applied, the needles dissolve in the skin, allowing the active ingredients to be injected directly into the skin. When drug ingredients are contained in a matrix, it is a Transdermal Drug Delivery System (TDDS) that delivers the drug through the skin. Compared with injection needles and existing metal microneedles, self-dissolving microneedles have the advantage of eliminating the risk of needles remaining in the body or leaving sharp waste that can be a biohazard.

Takei Lab. applied gas-permeable porous molds to fabricate ultrafine hyaluronic acid self-dissolving microneedles 80 µm in length compared to existing microneedles (100–1000 µm in length). Ultra-fine microneedles have the advantage of being less painful and allowing for a gentler increase in the blood levels of pharmaceutical ingredients. We are also developing jagged-tip self-dissolving microneedles that can be easily and painlessly self-administered without the need for injections, using mosquito needles and biomimetic technology.

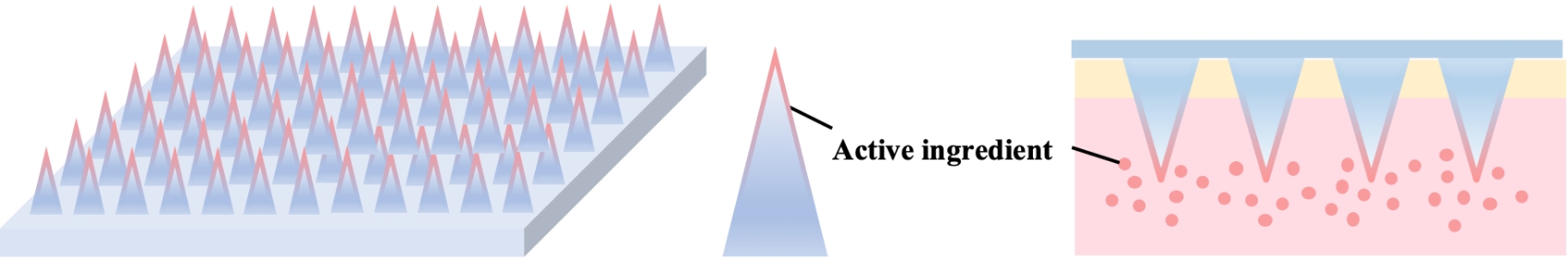

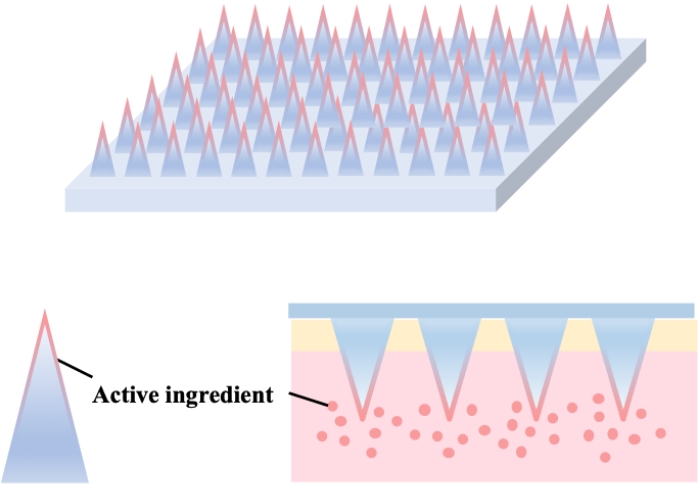

Type2:Active ingredients coated on the surface of the needle

Needle coatings are typically composed of fine pores or dissolvable materials. This allows the active ingredients to be released into the skin at a predictable and controlled rate. This is important for optimizing the effectiveness of the treatment. It is also possible to coat multiple active ingredients to achieve therapeutic effects simultaneously.

Takei Lab. developed drug-coated ultra-fine microneedles by using water-soluble resist coating technology and ultra-thin film-forming technology of extreme ultraviolet (EUV) lithography, even when the drug cannot be contained in the matrix or excipients.

Biocompatible medical device materials

Catheters, artificial blood vessels, artificial urinary tubes, and medical devices that do not cause stress to the body

Biocompatible medical devices such as absorbable sutures, absorbable tissue reinforcement materials, and artificial skin are molecularly designed to have minimal interaction with the body and can be used for safe and effective medical purposes. These biocompatible medical devices allow for optimized patient interaction and proper compatibility with the living body, and are expected to be the next generation of medical devices. In addition, antifouling polymeric materials and biomimetic surface function expression have attracted attention for their ability to prevent early occlusion and difficult removal of catheters, artificial blood vessels, and artificial urinary tubes owing to the adhesion of foreign substances such as calculus and digestive juices.

The development of biocompatible medical device materials that do not stress the body involves biomaterials, surface treatment technology, and bioengineering, the goal of which is to minimize the impact on the patient and maximize the therapeutic effect.

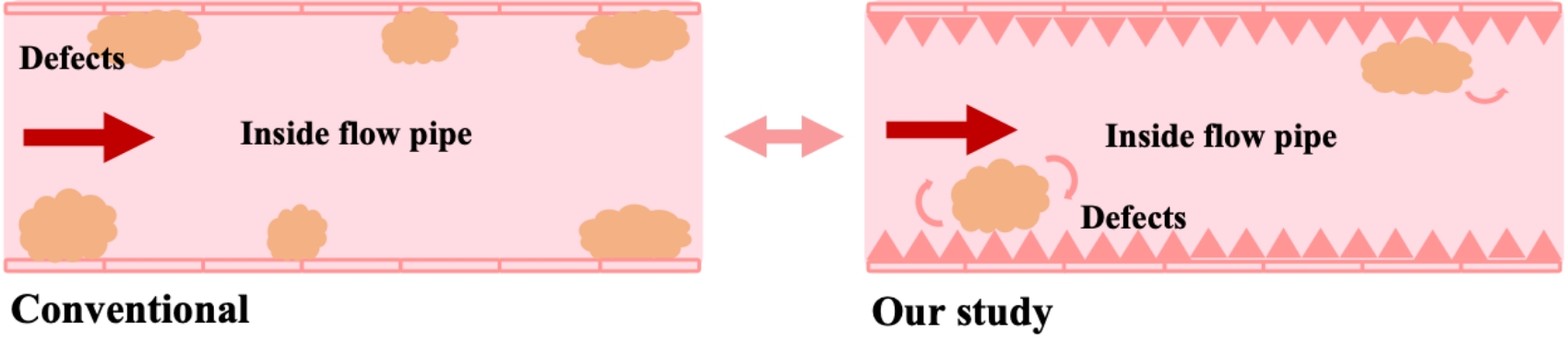

Takei Lab is developing soft gas-permeable porous flexible molds and molds that can be adapted for nano protrusions inner walls and inner surfaces of medical devices (catheters, artificial blood vessels, artificial urinary tubes) that can prevent adhesion of calculus and digestive fluids, and for ultra-fine processing of curved surfaces. Use gas-permeable porous flexible molds, extrusion tube molding, three-dimensional and curved surface processing, and roll-to-roll molding of antifouling polymeric materials have been developed to prevent defect adhesion. Functional materials with enhanced value-added properties of biomimicry, functional expression through surface microfabrication, and antifouling properties have attracted attention not only in the life sciences and healthcare fields, but also in the electronics field, and have grown to the point where we can collaborate with world-class research institutions and major companies both in Japan and overseas. We developed new eco-friendly products not only in the pharmaceutical field, but also in cosmetics, food products, semiconductor materials, and packaging films.

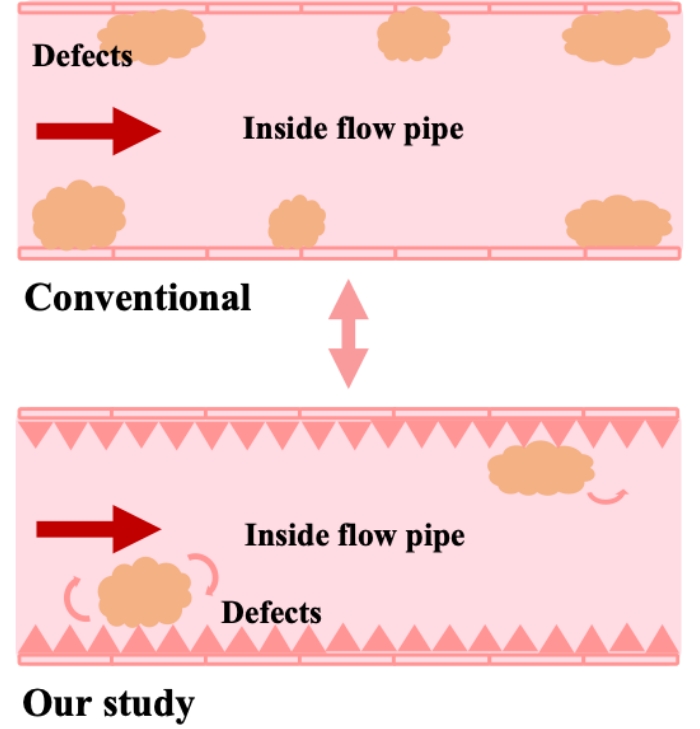

Food freshness sensor

Freshness and spoilage inspection for foods

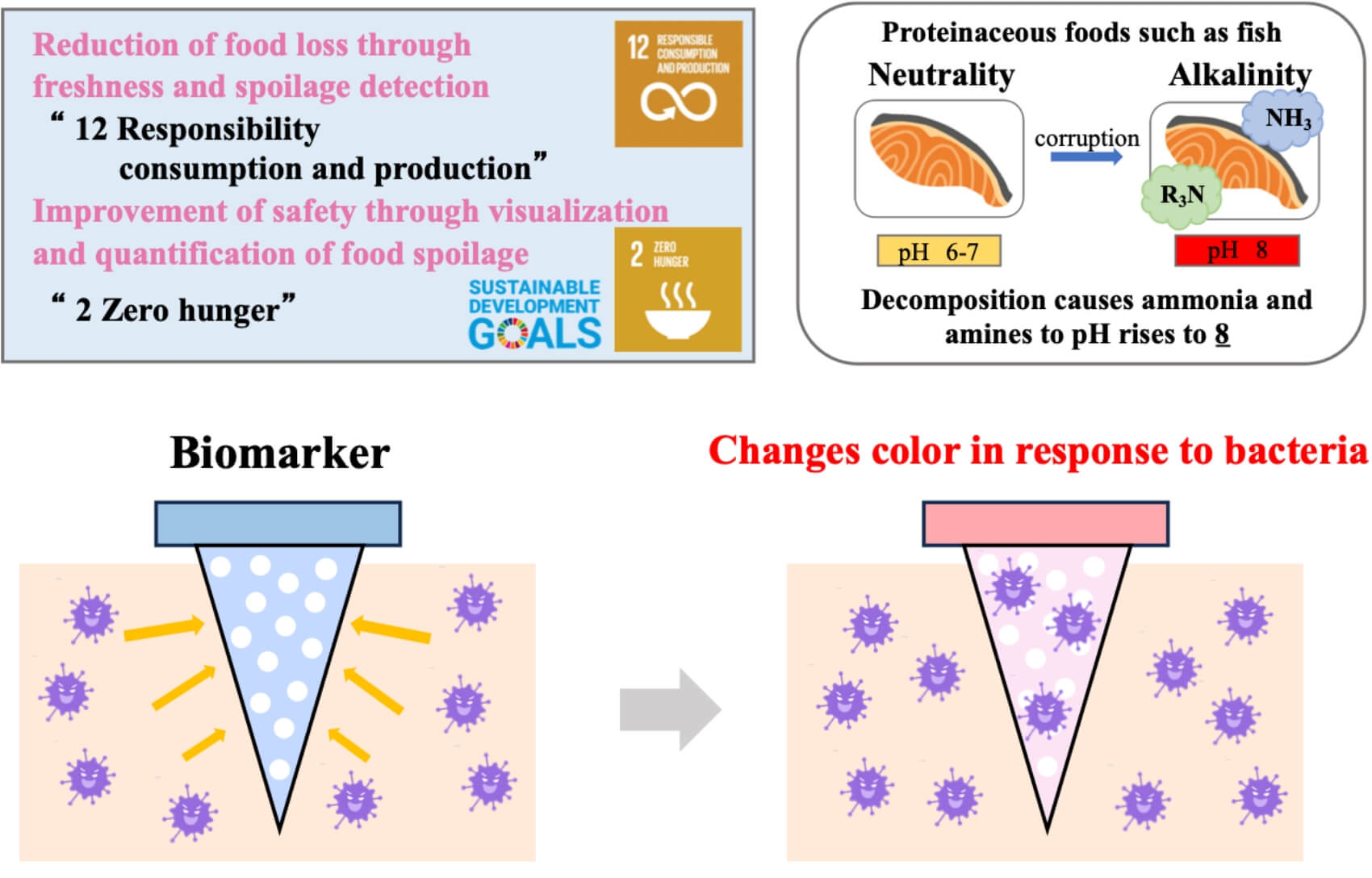

Sensing devices and sensors that can visualize and quantify food freshness and spoilage are expected to be used in inspection kits to monitor and evaluate food freshness and quality. Non-contact electronic devices equipped with sensing devices and sensors that can quantify the freshness and spoilage of food products have been marketed previously; however, issues have been pointed out regarding the accuracy of freshness and spoilage in certain food products. The contact-type food freshness/spoilage inspection kit, which can detect food changes and signs of spoilage, is disposable and easy to use. These advantages lead to food loss reduction through accurate and quick freshness and spoilage detection (SDGs 12) and improved safety through food spoilage visualization and quantification (SDGs 2). Freshness and spoilage test kits for food products have the advantage of making it easy for manufacturers, consumers, and distributors to check the freshness of food products.

Biomarkers are used to detect changes in the freshness and quality of food. Food safety can be confirmed by using the effect of biomarker discoloration in response to bacteria in food products that are undergoing spoilage during food distribution.

Takei Lab. selected edible raw materials and biocompatible polymers made of edible materials as the matrix for ultrafine microneedles, and research to add value and differentiate the ultrafine microneedles by integrating the porous and highly gas-permeable sensing needles, which can visualize and quantify the freshness and spoilage of food, with biomarkers corresponding to changes in the pH of spoilage of target foods. We are developing an inspection kit that can detect the freshness and spoilage of food in a very short time and with high accuracy by puncturing the food using a sensing needle and detecting color changes.

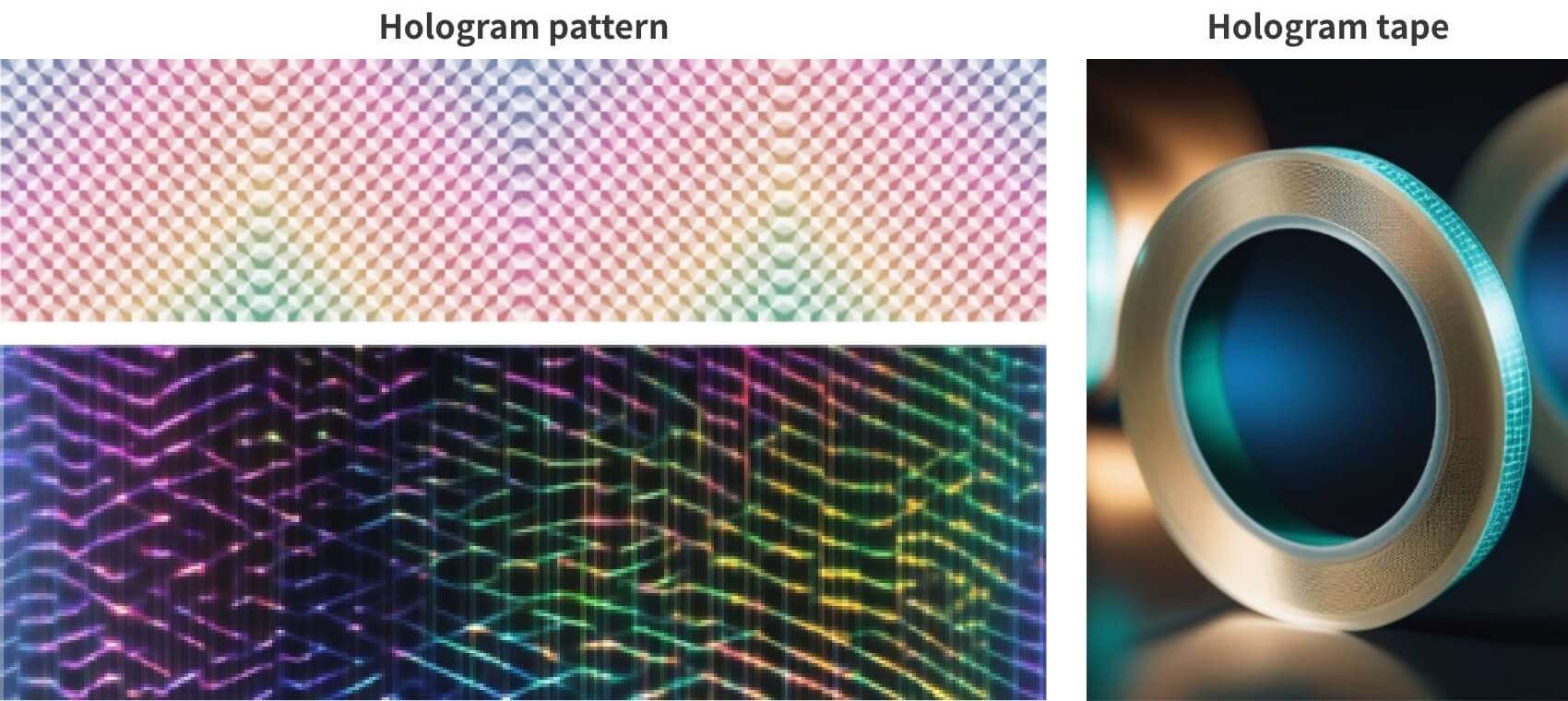

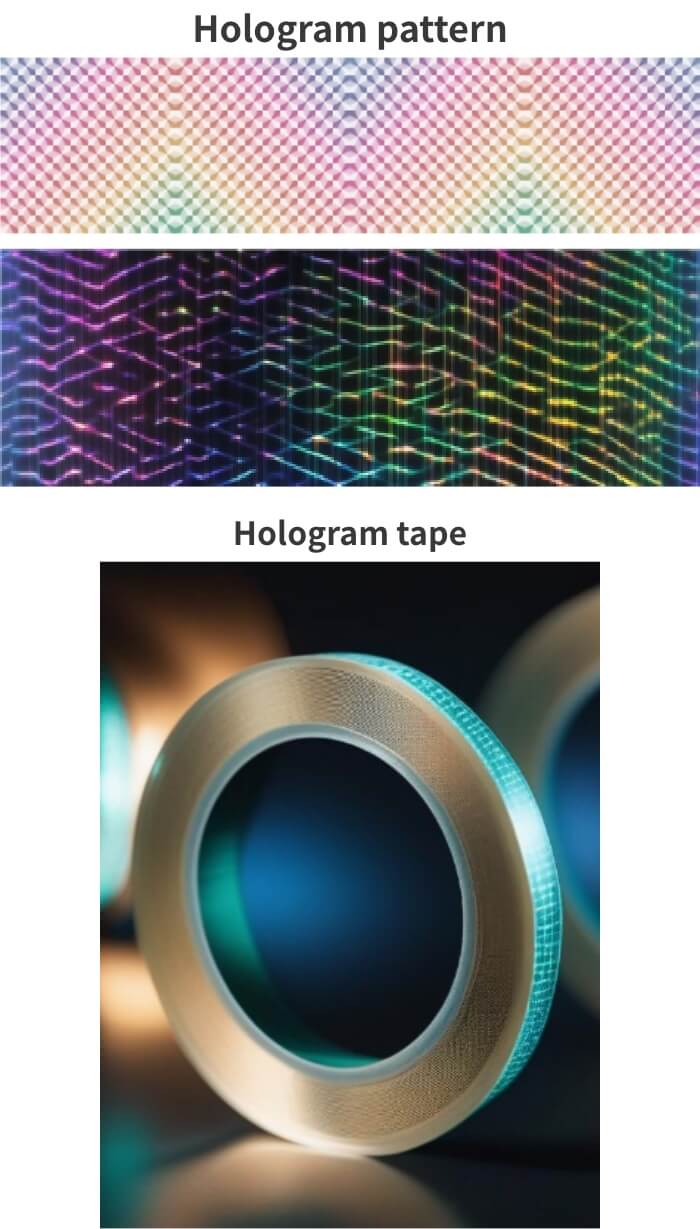

Edible hologram

Holograms to prevent food counterfeiting and mislabeling of place of origin

Anti-counterfeiting holograms for food products and place of origin are security and brand protection technologies with special features to confirm the legitimacy and authenticity of a product and demonstrate its authenticity to consumers. The unending expansion of food quality fraud and a disguised place of origin has become a global problem that threatens human health and safety.

Holograms usually have complex three-dimensional patterns and create unique visual effects by reflecting and refracting light. The structural color, luster, three-dimensionality, and gloss are different from those of the printed materials and have complex patterns, making them difficult to counterfeit. Anti-counterfeiting edible holograms for food products and places of origin are visually decorative, yet the holograms themselves are composed of materials that are safe for food and do not affect health. It creates a three-dimensional visual effect and provides an intuitive indication of product authenticity. The change in perspective and angle of light provides clues as to whether or not the hologram is legitimate, which allows consumers to easily verify the authenticity of the product, manufacturers, and brands to improve the credibility of their products.

Conventional tape and seal materials used for holograms of non-plant origin are generally toxic and inedible. Furthermore, conventional hologram materials are coated with organic solvents and developed with organic solvents, which causes contamination with food products and packaging packages.

Takei Lab. is working on improving the characteristics of edible hologram materials (anti-counterfeiting), which can prevent fraudulent food quality and place of origin, by devising water-soluble patterning materials (resist materials), which are our research originality, and laminated coating technology for holograms to prevent food counterfeiting and production area counterfeiting. In addition, we are promoting social implementation by establishing production technologies that can reduce manufacturing costs through intellectual property, the provision of prototypes, and technology transfers. We will contribute to the restoration of confidence in the food sector, including marine products, which is the flagship industry of the region (Toyama), and to strengthening the industrial strength of high value-added functional materials, which is Japan’s forte.

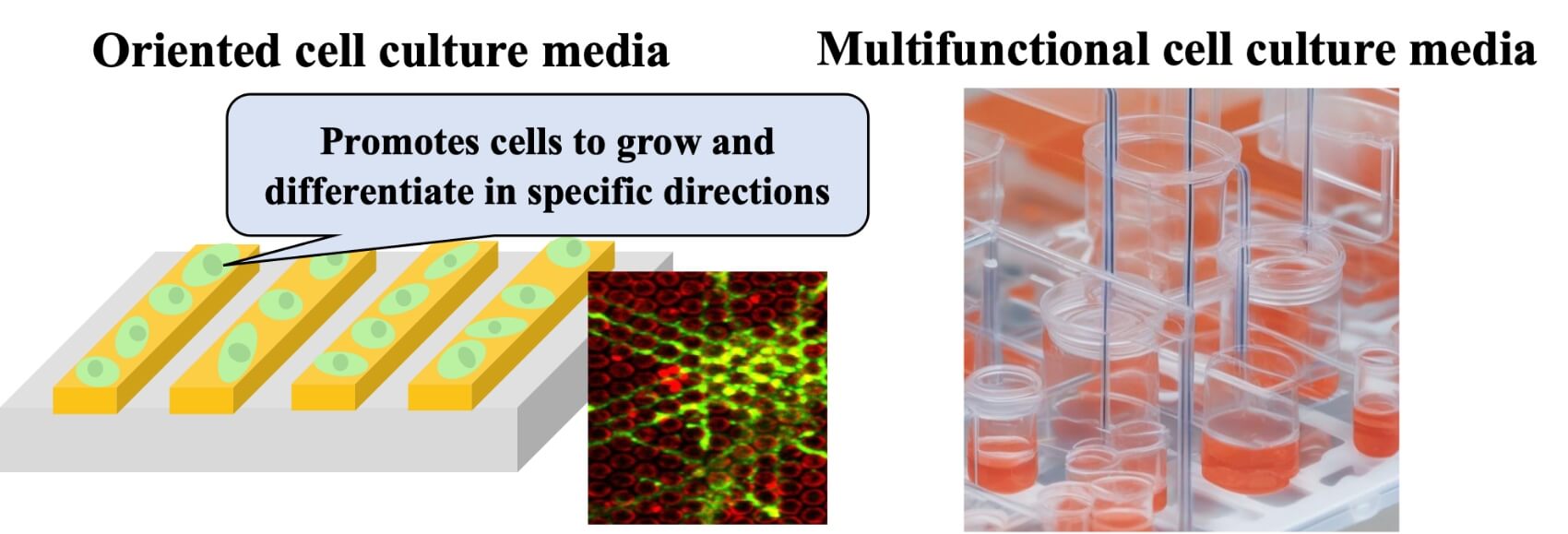

Cell culture medium

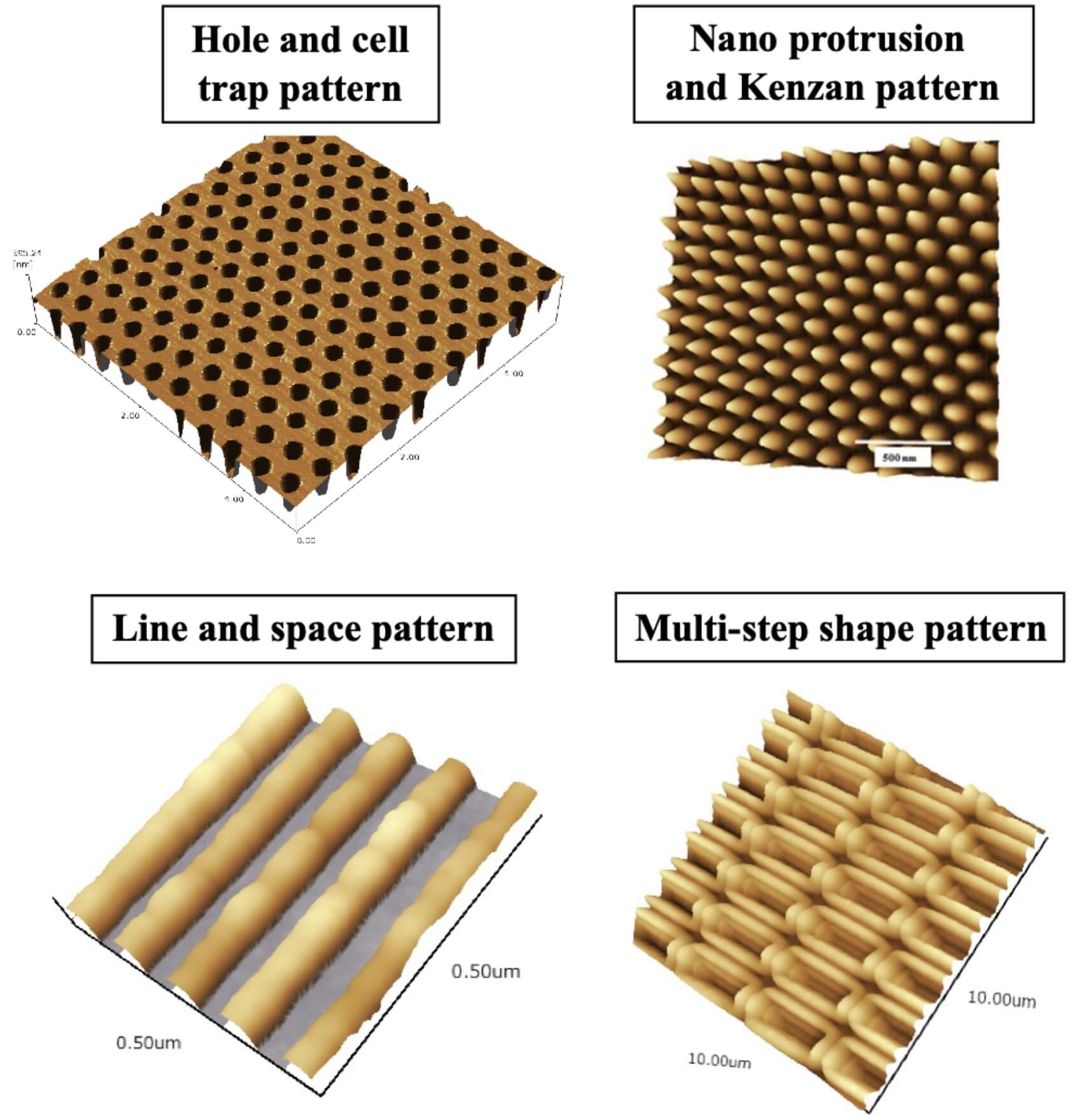

Oriented cell culture medium, multifunctional culture medium with fine surface structure suitable for cell aggregation prevention and cell culture

Oriented cell culture media are designed to promote cell growth and differentiation in a specific directions. This supports the formation of tissues and structures, and allows cells to function in a physiological state. In addition, certain cells may aggregate in the height direction in the existing smooth media, which is inconvenient for analysis. There is a growing market demand for multifunctional culture media with fine surface structures suitable for preventing cell aggregation and cell culture.

Oriented cell culture media control the direction of cell movement and division, forming specific patterns and structures that allow for more sophisticated studies of cell behavior and tissue formation. In the field of tissue engineering, it is used as a basis for building tissues with cells aligned in a specific direction. This is beneficial in situations where the orientation of cells within a tissue is important, such as in cardiac or neural tissues. In addition, the use of culture media facilitates cell sheet extension in specific directions, making it easier to track and analyze cell dynamics and morphological changes, thus facilitating experiments that focus on cell behavior. Oriented cell culture media are suitable for culturing cells with a specific orientation and make an important contribution to tissue engineering and studies of cell behavior. In addition, analytical cell agglutination media that make cell agglutination difficult, and multifunctional culture media that increase the growth rate of bacteria by increasing the surface area of the culture medium with holes or columns that are shaped to suit the cells to be cultured are attracting attention.

Takei Lab. is developing molecular designs and prototypes of water-soluble patterning materials (resist materials) and lithography techniques that are ingeniously improved to contain nutritive components that can cultivate specific cells. Water-soluble patterning materials allow the use of nutrients and hydrophilic materials for cell culture,which cannot be used with conventional resist materials and are not cytotoxic. We are attempting to fabricate multifunctional cell culture media that can selectively create areas to which specific cells adhere or do not adhere by microfabrication for life science applications using water-soluble patterning materials.

Beauty sheets

Medical art makeup, art hair, high penetration cleansing, and Multifunctional sheets for traceability

Medical art makeup/art hair sheets are techniques that use paramedical pigmentation to create aesthetic and artistic effects on the face and body. Unlike tattoos, which the pigment is permanent, medical art makeup/art hair fades after a few years and can be designed and color changed according to the patient’s own skin conditions and treatment recovery trends. In addition, high penetration cleansing sheets are special cleansing products made to fit the microscopic irregularities of the skin’s surface to effectively remove makeup and sebum.

Medical art make-up and art hair is a long-lasting “indelible makeup” that does not come off even when wet or sweaty and is performed at medical institutions. It has become a convenient cosmetic procedure, as well as a side effect of anti-cancer drug (chemotherapy) treatment, radiation therapy, and certain skin diseases. Unlike everyday makeup, there are reports that it is more lasting and maintains beauty for a longer period (several years). Partially customizable to individual treatment situations and lifestyles, dye transfer is possible by applying a biocompatible ultrafine microneedle sheet containing dye to the skin.

Takei Lab. is researching biocompatible ultrafine microneedles/art make sheets for traceability in the livestock industry to provide a safe and stable supply of livestock products such as milk, beef, pork, chicken, and eggs. In addition, the cleansing sheet features a microfabricated sheet that conforms to the skin and gently removes the foundation, eyeliner, and lipstick without stressing the skin. We are researching beauty sheets that adhere firmly to the skin and gently remove even the smallest details of hard-to-remove eyeshadows and eyeliners. The prototype beauty sheet eliminates the need for scrubbing. We are conducting cosmetology research on cosmetic beauty sheets that have various irregularities and can achieve a high surface area.